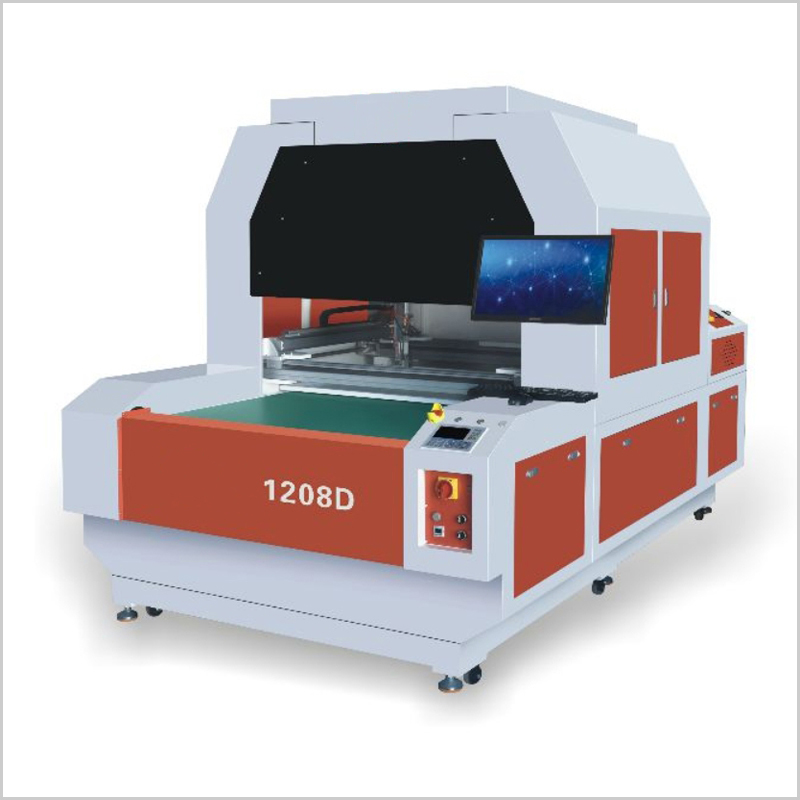

Shoe Upper Flattening Hot Air Seam Sealing Tape Machine

Shoe Upper Flattening Hot Air Seam Sealing Tape Machine

characteristic:

1.Because the factory has a variety of specifications and different materials, the upper and lower pressing wheels of the machine can be quickly disassembled and replaced to adapt to different processes, meet the needs of different materials, and solve the problems of deformation, wrinkling, heel protruding edge line and so on caused by different materials

2.According to the materials of different shoe types, combined with the unique pressing wheel structure, the distance between the pressing wheel and the pressing wheel can be accurately adjusted to make the fitting more smooth, firm and difficult to separate.

3.The unique design of computer-controlled automatic belt feeding function can accurately control the belt feeding length, effectively control the cost and avoid waste.

4.Unique automatic belt cutting function, accurate automatic belt cutting, reducing manual belt cutting cost and improving efficiency.

5.The unique reinforcing belt is matched with the specially designed rolling structure, which has better fitting effect, no marks and particles, which can save the process and improve the quality

6.The unique design of automatic edge dividing structure can save the manual edge dividing process and improve the rolling quality and efficiency. (patented)

7.The unique design structure eliminates the manual hammering process and can be hammered automatically to improve the rolling quality and efficiency

8.The special feeding system with adjustable speed can adapt to different materials, and the process can be set and adjusted to improve the production efficiency.

9.It has the pressing function of waterproof edge, and can fit the waterproof edge only by replacing the high-efficiency electric heating tube mechanism

10.The unique design of curved arm synchronous feeding structure can meet the functions of rolling, reinforcing and fitting of materials with various shapes and curvature. (patented)

eleven

The machine has the function of data memory and storage. According to the materials and processes of different lengths, it can set the data such as automatic cutting, automatic feeding length and rolling length. It can be memorized in multiple sections and output in batches, which can improve the production efficiency and standardization.

twelve

The machine is equipped with full-color touch man-machine interface, which is fast, simple and convenient to operate.

|

Model |

motor |

Power |

pressue |

production |

N.W |

Machine size |

Packing size |

|

DF-226B |

0.55KW |

2KW |

0.3Mpa |

1500Pairs/8Hs |

120KG |

1060×700×1500mm |

1160×760×1650mm |