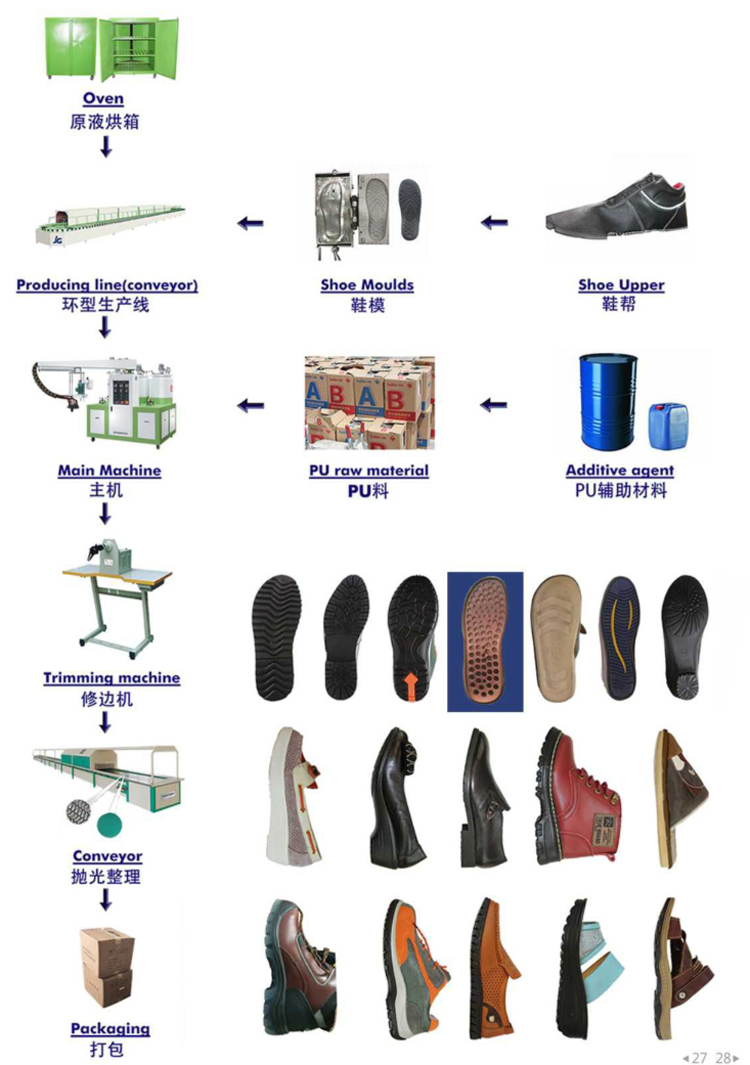

Sport Safety Shoe Pu Foaming Pouring Sole Injection Moulding Making Machine

Sport Safety Shoe Pu Foaming Pouring Sole Injection Moulding Making Machine

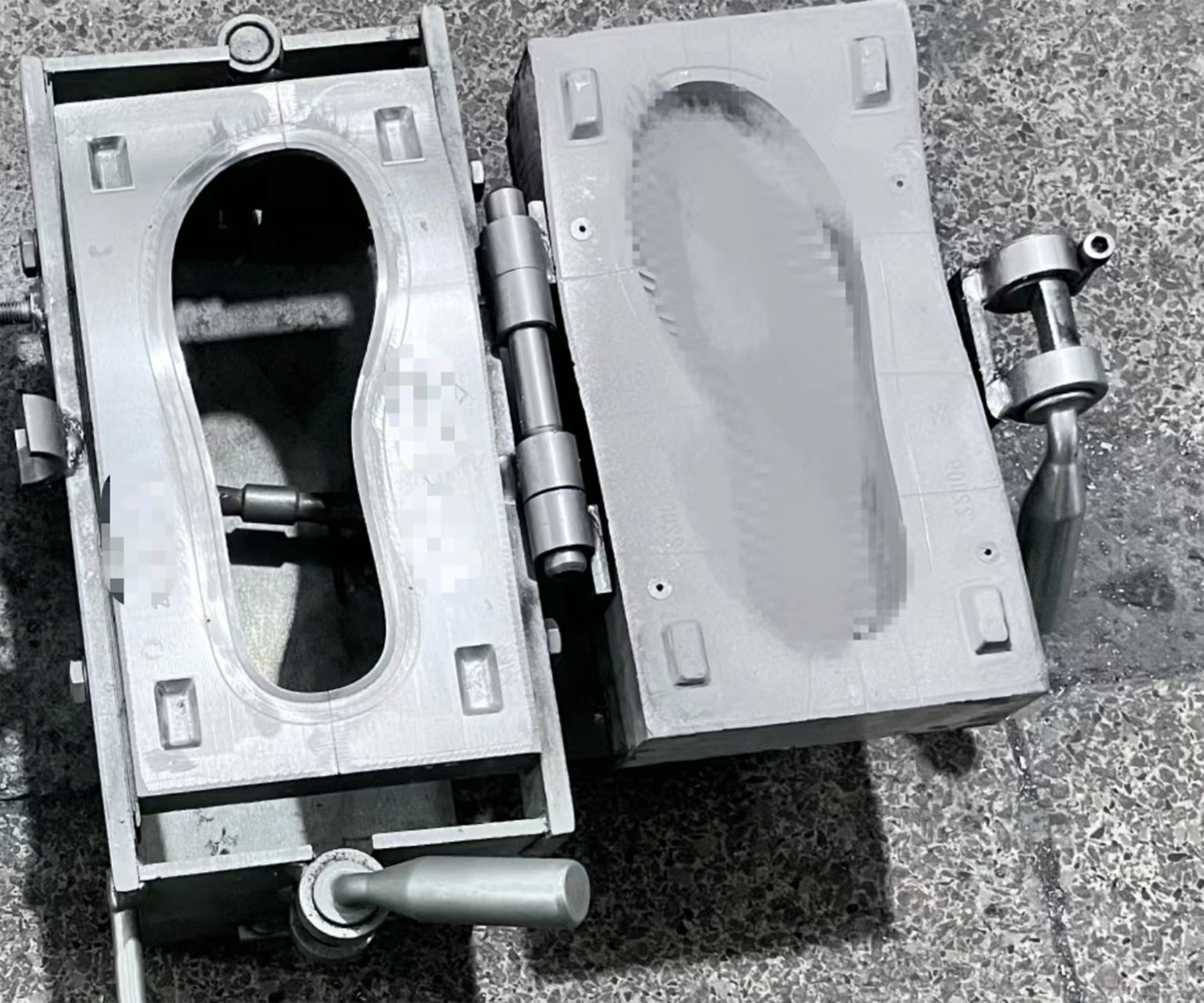

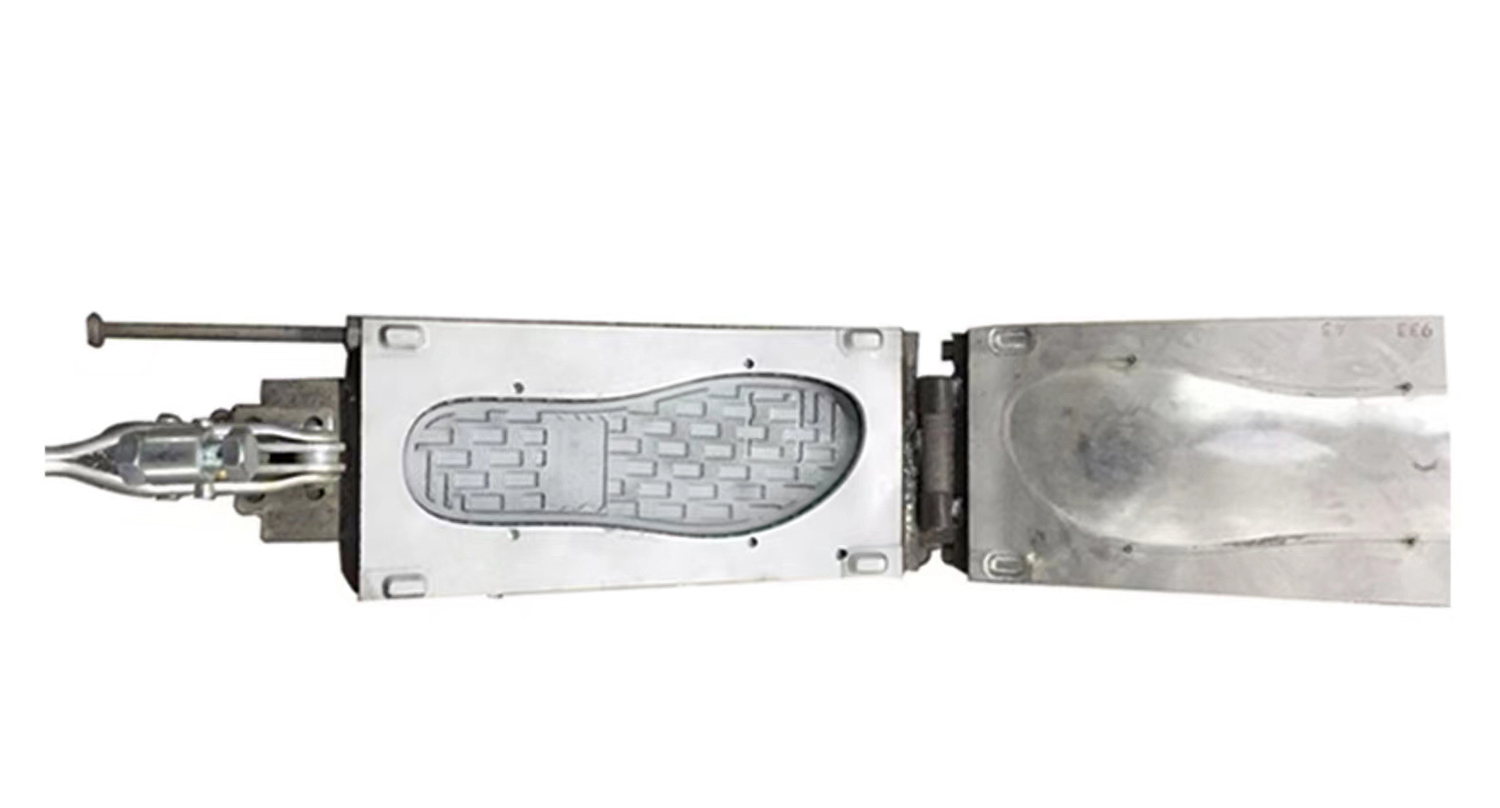

mould

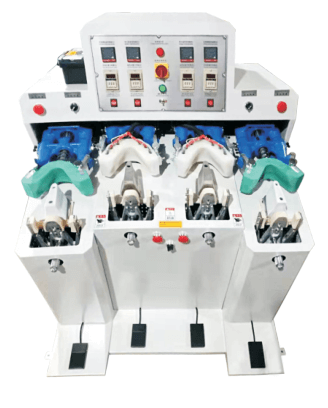

DF-701 Single color PU shoe ( sole ) pouring machine

2 tanks, capacity of each tank: 160L or 250L

Characteristics:

1. Have one A tank and one B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with two needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

Characteristics:

1. Have one A tank and one B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with two needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

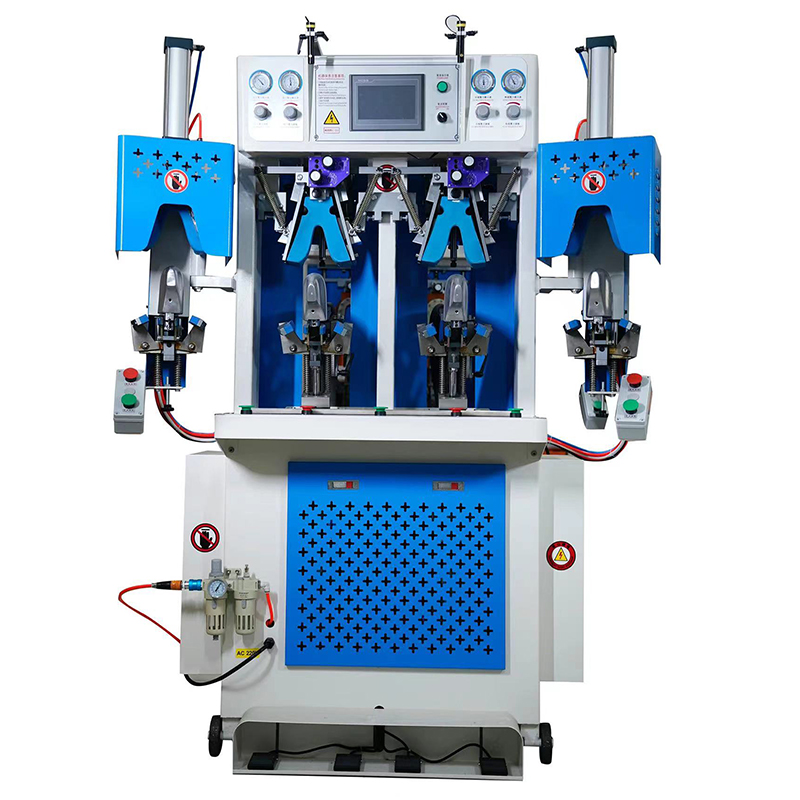

DF-702 Double color PU shoe ( sole ) pouring machine

3 Tanks, capacity of each tank: 160L or 250L Can make two colors two density PU shoe sole

Characteristics:

1. Have two A tank and one B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with three needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

Characteristics:

1. Have two A tank and one B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with three needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DF-703 Double color PU shoe ( sole ) pouring machine

4 tanks, capacity of each tank: 160L or 250L

Can make two colors two density PU and transparent PU shoe sole at the same time

Characteristics:

1. Have two A tank and two B tank, can make different density and different color foaming outsole, by mix each A and B under

requirement. Especially advantage in double pouring head can make transparent polyurethane outsole at same time.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with four needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

Characteristics:

1. Have two A tank and two B tank, can make different density and different color foaming outsole, by mix each A and B under

requirement. Especially advantage in double pouring head can make transparent polyurethane outsole at same time.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with four needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DF-705 Three colors PU shoe ( sole ) pouring machine

4 tanks, capacity of each tank: 160L or 250L

Can make three colors three density PU shoe sole

Characteristics:

1. Have two A tank and two B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with four needle which can work independently.

3. Heating system with electricity, make heating more fast and more eficient in power saving.

4. Self- developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

Can make three colors three density PU shoe sole

Characteristics:

1. Have two A tank and two B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with four needle which can work independently.

3. Heating system with electricity, make heating more fast and more eficient in power saving.

4. Self- developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|