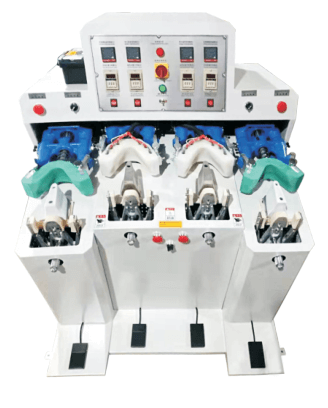

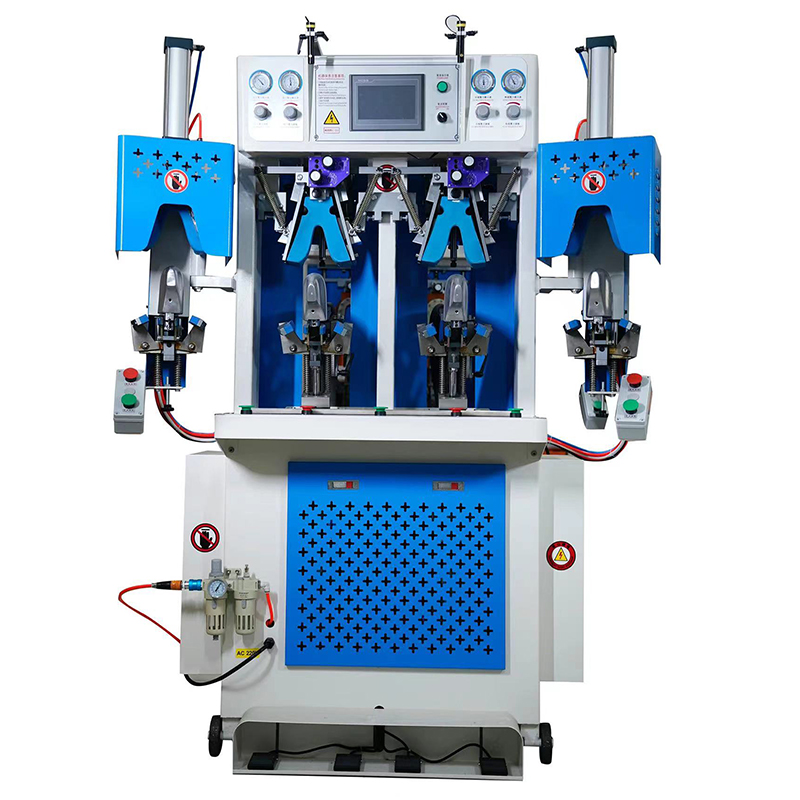

Sports Shoe BackPart Moulding Molding Machines,Footwear Machines

sports Shoes BackPart Moulding Molding Machines Making Shoes

Characteristic:

1.High efficient double cold and hot mould set ensures high output.

2.The temperature of both the inner and outer part of the hot mould can be adjusted separately to meet different heating requirments of various kinds of upper and lining material.

3.After the back counter pre-moulding process,the upper and lining will be attache tightly and smoothly to retain superior quality and less reject ratio.

4.Slant operating platform enables easier and more convenient operation for the operator.

5.The switch of adustable clamp can be turned offifnot in need so as to be applicable to various kinds of shoes.

6.Custom-made last mould offers the highest accurancy.

7.The special inverse mould can be used to reshape the rejects to remove wrinkles and keep perfect appearance of topline.

8.Uniquely designed environmentally-sound cooling system boasts the best cooling effect with high efficiency.(vaporizer temperature drops to -20c after 10 minutes normal running)

|

MODEL |

Dimensions(LWH) |

Packing size(LWH) |

Weight |

Production |

Power |

Voltage |

|

DF-967B |

L1080*W930*H1460MM |

L1090*W940*H1470MM |

280KG |

1400~2000PAIRS/8HRS |

3.5KW |

220V |