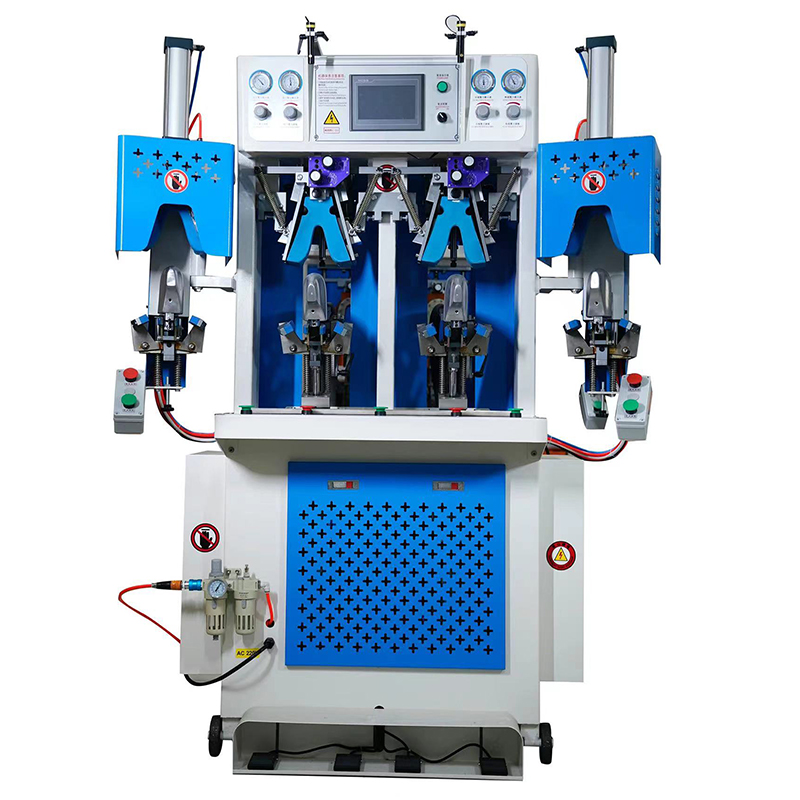

Shoe Counter Back Part Moulding Molding Machine,Shoes Machine

Shoe Counter Back Part Moulding Molding Machine,Shoes Machine

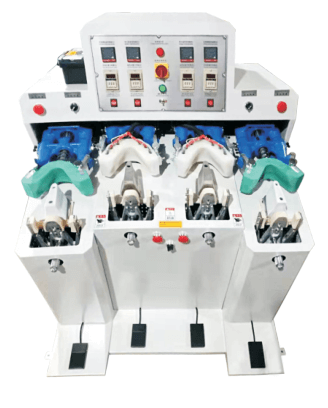

In order to meet customers' request, we offer this new counter moulding machine. The ALFA 202 is with two pre-heated stations plus two cold stations. Equipped with chilled moulds and plates for folding over seat edges for standard flat lasting, but with possibility to change working upper to deal or good year flanging in very short time. Only need to change the flanging wipers,this machine has a special mechinical quick change support and select the specific process on the control panel. Mod. ALFA 202 machine keeps features of mod .684CF2HP that is:

◆Control panel introduce any kind of set data values of machine cycle, hot and cold mould temperature and also receive warning in case of malfunctions.

◆Cold moulds are always made with the shape of customers' sample last.

◆Complete adjustment for outer and inner moulds, flanging wipers and pincer gives the possibility to use of baby size to men size including skating boots.

◆Optical projector or pneumatic positioning upper equip with wipers for molds.

◆The operating cycle is marked by the column moving up to the rubber cushion, then it gets close to make closing wiper movement and ironing over seat edges. Mod. AIFA 202 is a complete machine with full fanction. Including wipers for normal shoe and working shoe.

◆Two stations are equipped with heated moulds and plates for folding over seat edges .

◆Four stations are equipped with chilled moulds and plates for folding over seat edges plus two pre-heated stations with upper pulling pincers.

◆Safety photoelectric switch system.

◆Independent pre-heated station with upper pulling switch

|

MODEL |

Dimensions(LWH) |

Packing size(LWH) |

Weight |

Production |

Power |

Voltage |

|

DF-863B |

900X2050X2000mm |

1000X2150X2250mm |

820KG |

2200Pairs/8H |

3.2kw |

220v |