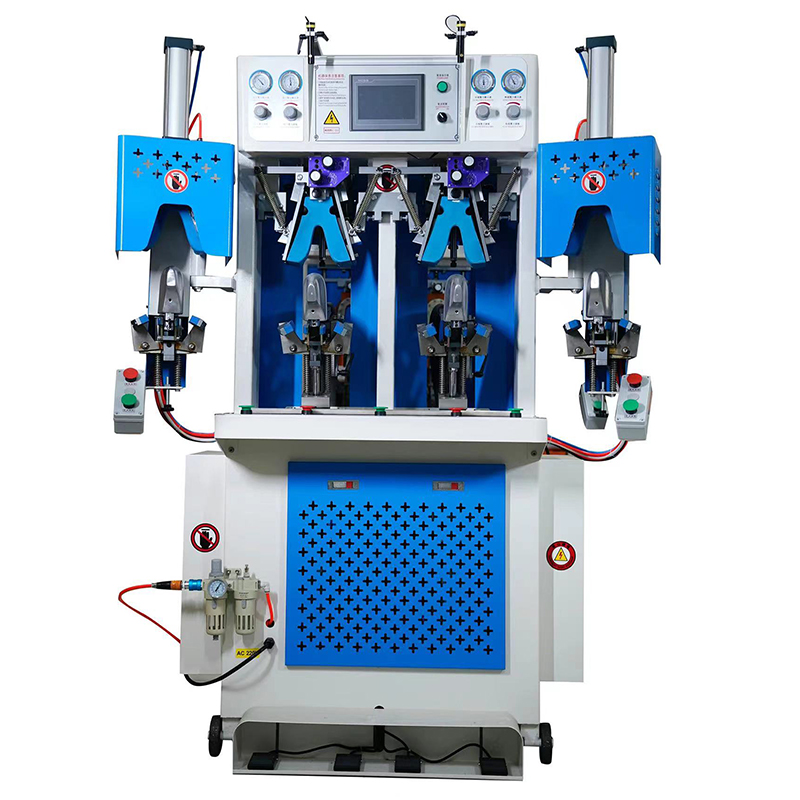

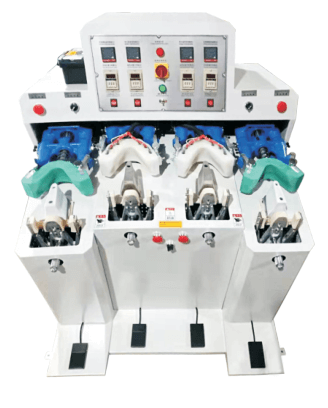

Shoe Counter Molding Maker Machine,Shoe Manufacturing Back Part Moulding Machine

The outer edge of heel vamp can be folded and shaped at the same time.

2. Suitable for all kinds of materials.

3. Equipped with sweeper, adjustable vamp and other functions.

4. Tilting last is more convenient to operate.

5. The temperature of internal and external mold can be adjusted according to the material.

6. The internal and external molds can be customized according to the last of customers to obtain more perfect appearance.

7. Projection lamp can get the most accurate position.

8. The adjustable clamp makes the vamp and last fit 100%.

9. Environmental friendly refrigeration system is adopted, with fast refrigeration speed and freezing temperature up to minus 30 ℃.

10. After shaping, make the lining, film and vamp fit closely without wrinkling, deformation and blistering.

11. Microelectronic processing system.

|

Model |

Dimensions(LWH) |

packing size(LWH) |

Weight |

Production |

power |

voltage |

|

DF-861 |

890X850X1950mm |

990x950x2120mm |

260kg |

1200Pairs/8H |

2.7kw |

220v |