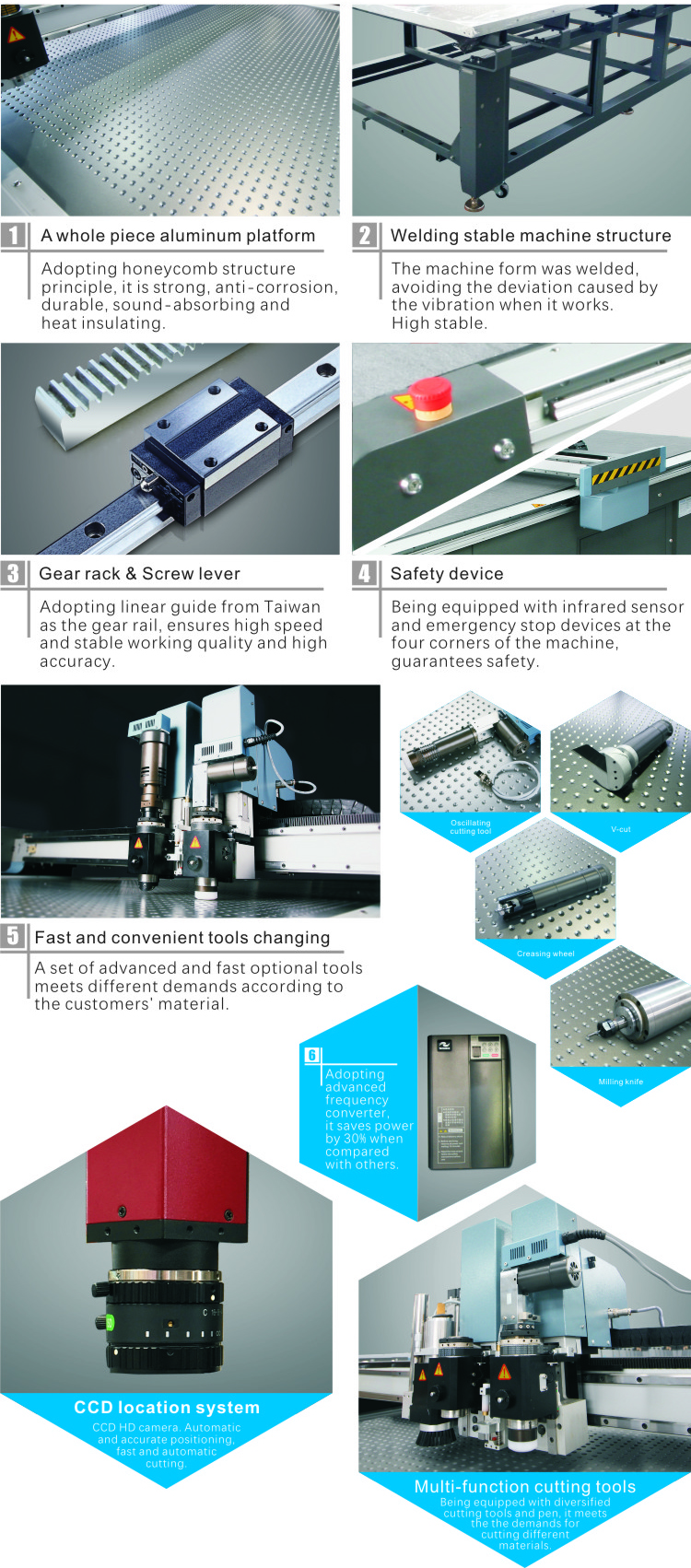

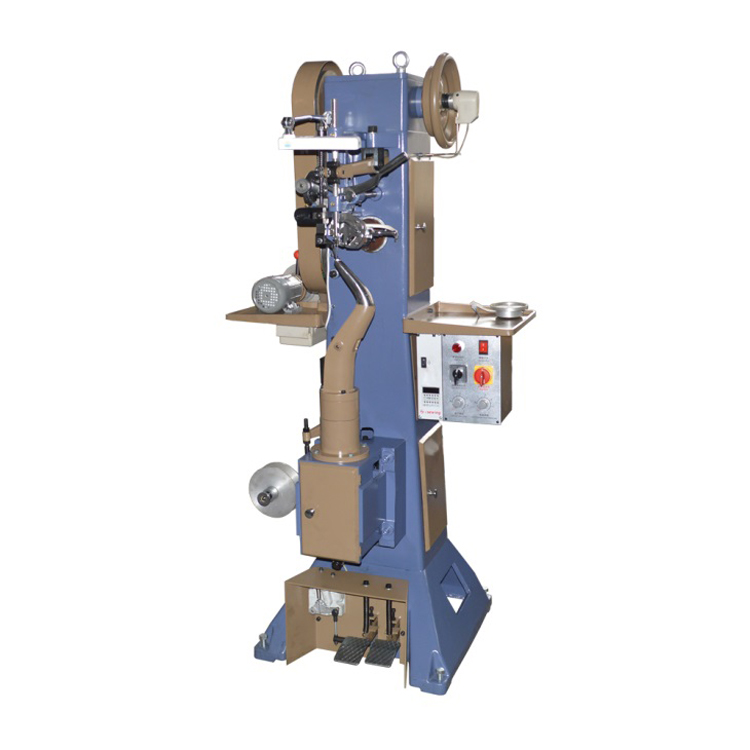

Automatic Dieless Digital CNC Vibrating Knife PU Leather Cutting Machine

Automatic Dieless Digital CNC Vibrating Knife PU Leather Cutting Machine

Applicable cutting materials: leather, PU, fabric cardboard, plastic board, Grey board, white board and gasket, etc.

Application: widely used in cloth, shoe, bag, footwear and leather wear industries.

Functions: cutting, drawing and punching.

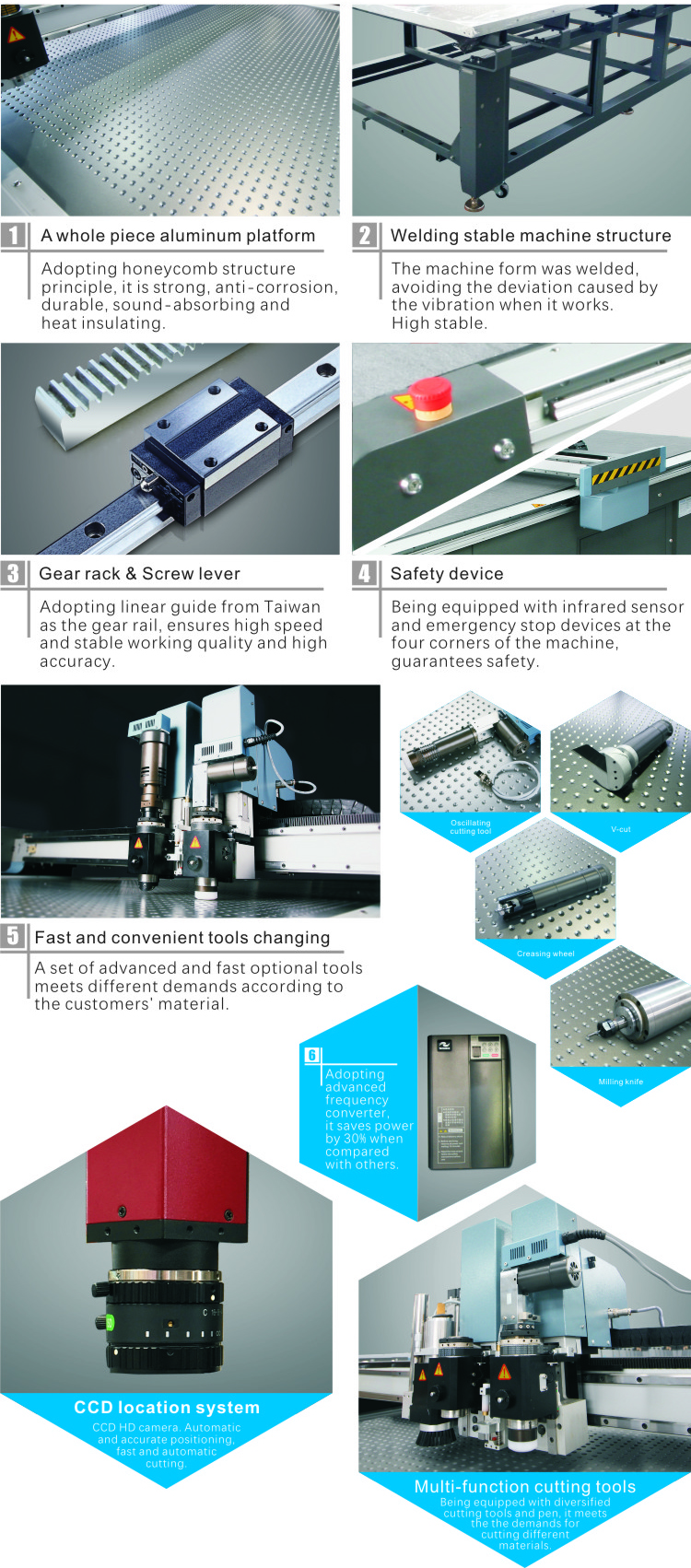

Equipment: combined cutting head, camera, projectors, automatic nesting software, etc.

Features: multifunctional, working time saving, labor forces saving and it improves the utilization of cutting materials.

Parameters of CNC leather Cutting machine

|

Model of cutting machine |

DFCUT-2516SF |

|

Effective working area |

2500mm×1600mm |

|

Cutting speed |

100-1200mm/s |

|

Cutting thickness |

0.5-6mm |

|

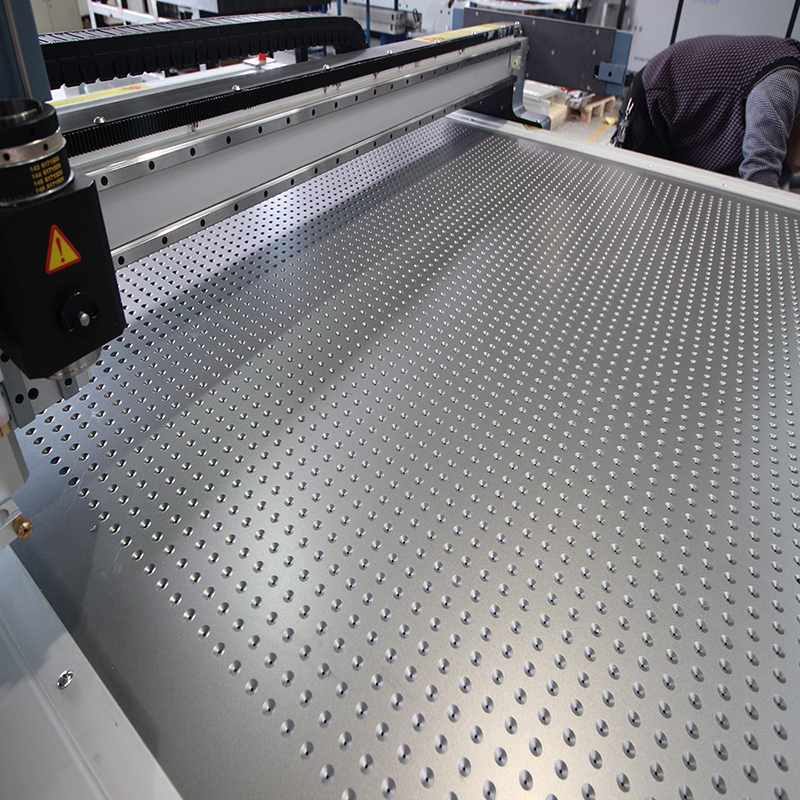

Method of fixing material |

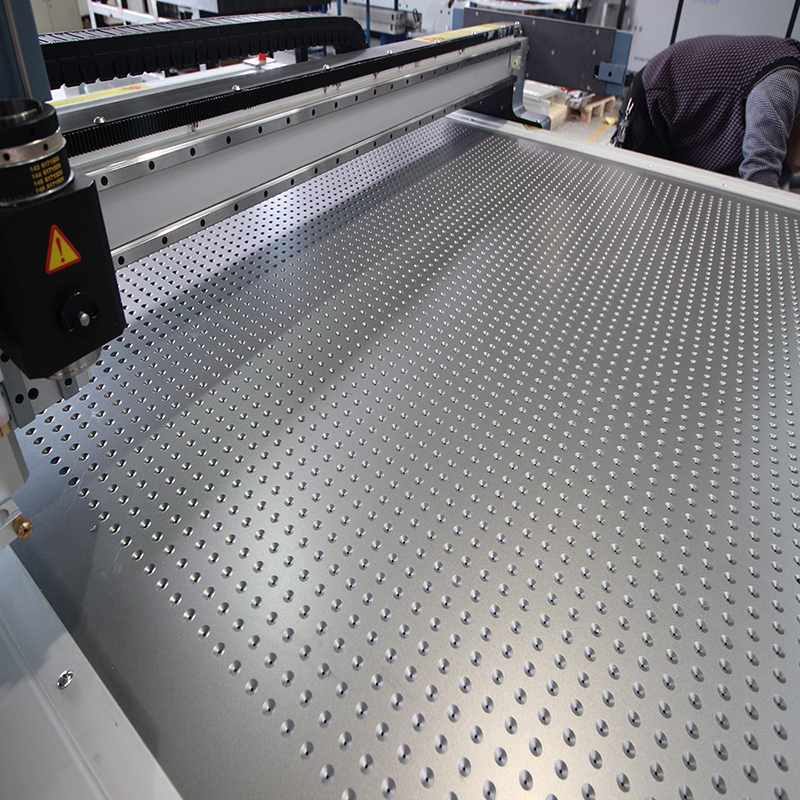

Divisional vacuum absorption |

|

Knife |

Oscillating blade head, Milling Cutter, Hobbing Cutter, Creasing Wheel |

|

Pen type |

Common signing pen, Oil pen, ball-point pen, Silver pen |

|

Human Machine Interface (HMI) |

Touch screen LCD |

|

Machine resolution |

0.01mm |

|

Software resolution |

0.025mm |

|

Interface of transmission |

Network port |

|

Command system |

HP-GL and GP-GL compatible formats |

|

Gearing |

Linear guide and gear rack |

|

Motor |

Servo motor |

|

Machine Working Voltage |

220V |

|

Air pump power |

9KW |

|

Energy saving device |

Frequency converter |

|

Safety device |

Automatic laser device |

|

Software system |

Independent research and development CNC software |

|

Control system |

Cutting table and computer display |

Tools and Functions

1. Vibrating Knife:

(1) Availability of accurate full-cut and half-cut, ruling out the defects cause by die cutter or laser cutter.

(2) Adoption vibrating knife cutting technology, it can create precise patterns on natural leather, synthetic material, etc.

(3) Completely replace of manual cutting and mould cutting, save material, time and money.

2.PROJECTOR:

Identfy flaws on the materials and capture the contour of the material, save material.

3.PEN:

Doing marks, drawing lines and creating pictures on the material, ball-pen / oil-pen / silver pen are optional.

4.PUNCHES AND BLADE:

Do punching automatically, various types of blades, choose them according to your specific demands.

5.LCD AND EMERGENCY BUTTON DISPLAY:

All you need to do is to operate the mouse to finish your production. Red button is used when some emergencies happen.

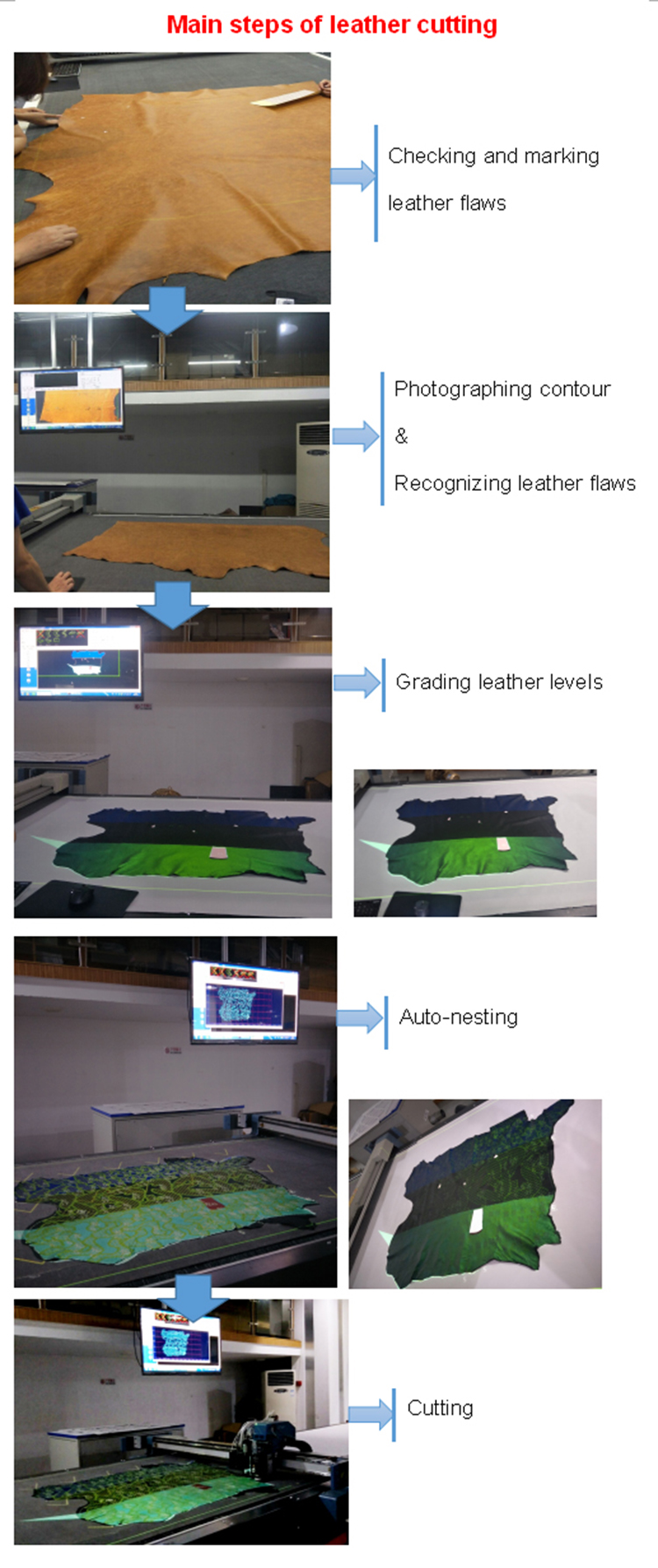

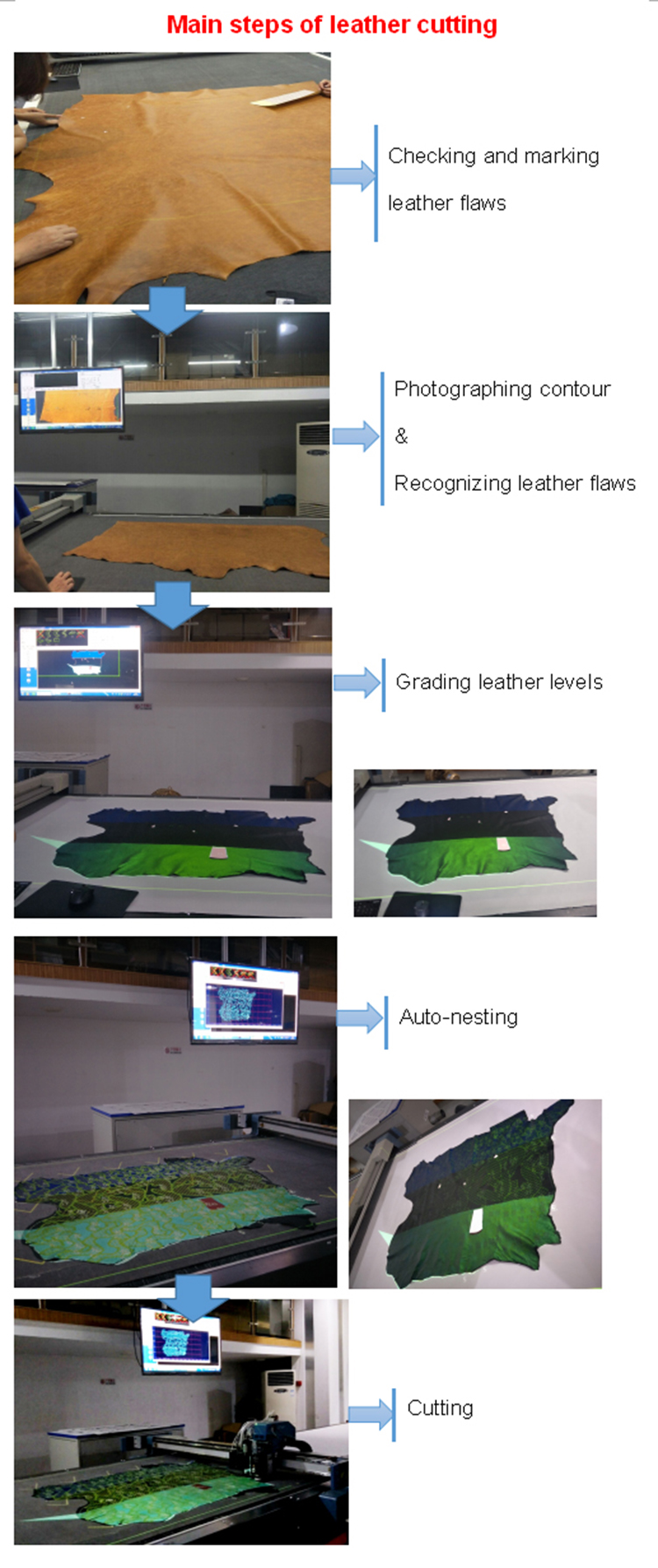

Main Steps of Leather Cutting

Leather Cutting Samples

Advantages

Advantages

The CNC leather cutting machines are packaged with standard export wooden case which can guarantee the cutting machines' safety.