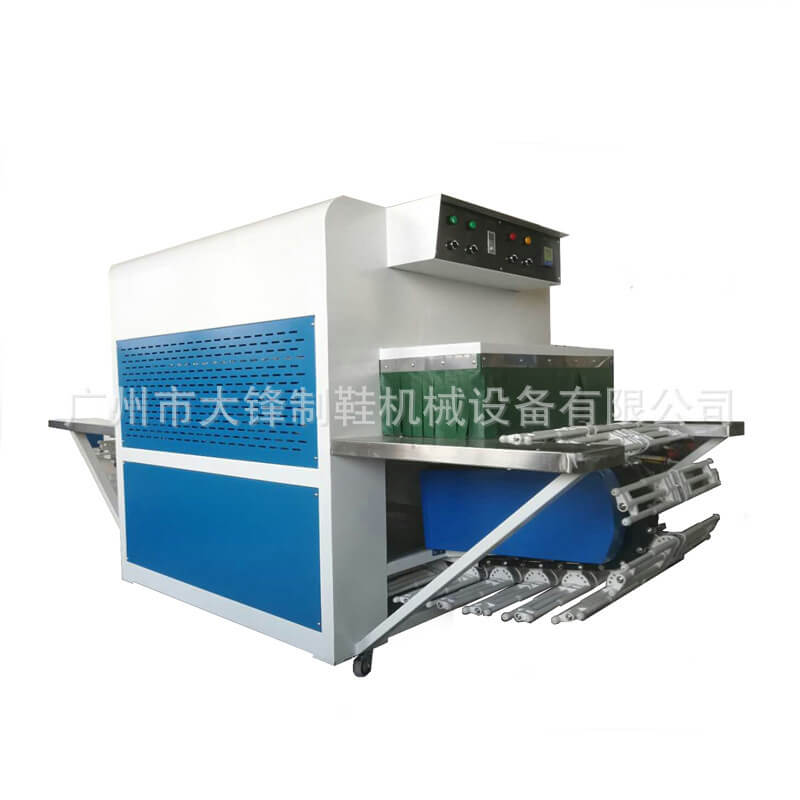

Rotary Vacuum Shoe Steam Heat Setting Machine,Shoe moulding machine

Rotary Vacuum Shoe Steam Heat Setting Machine

1.Upper Moist-Heating in hermetic chamber. With closed steam spraying, produces steam of high pressure and high temperature. With vacuum vaporizing to penetrate the vamp hence can reach a Moist

Heating setting effect.

2.With collecting hot air by acentric sirocco fan to vamp ironing, It can make the vamp`s crimple get a perfect shapely.

3.Upper Drying& Setting by Vacuum. The different material of upper(real skin, pu etc), the

different parts of the upper(toe, instep and heel etc) can be heated in different ways, this owing to the perfect shapely efficiency and also reducing power.

4.Small overall dimension, perfect shape, it`s well used in lean or sample product.

5.The heating and vacuum processing time could be adjusted for different shoe material.

|

Model |

Dimensions |

Voltage |

Weight |

Power |

Box size |

Output |

|

DF-904 |

2200*2200*1900 |

380V |

900KG |

15KW |

800*800*350 |

1200Pairs/8h |