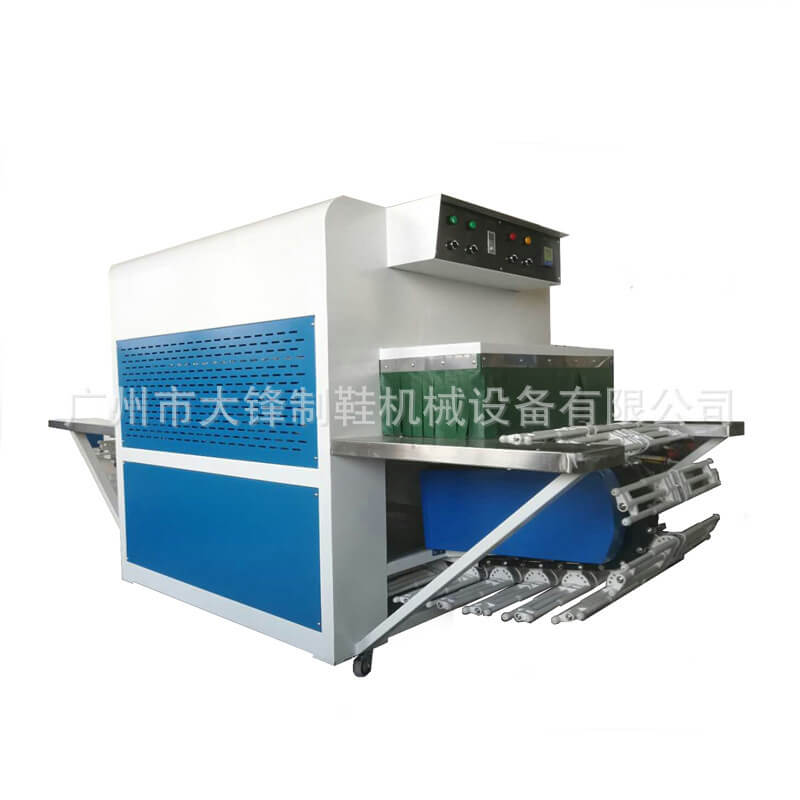

Double Layer Shoe Sole Attaching Assembly Line Shoe Cement Drying Activator Machine

Double-layer infra-red sole attaching assembly line cement drying and activator

Adopt two layer conveyor, up layer for outsole while down layer for vamp. The oven can control and setting the temperature independently based on different material, which will reach quick heating and high efficiency. It cost only 1/3times of the traditional electric oven and save space and electric heating greatly.

With imported low dazzle-light NIR lamps to heat the glue inside and outside equably, cooperate with circular system , it can dry and activate the glue quickly and steadily .

inspiration and exhaust device put on the oven and glue -scrapping worktable which completes exhausting the vapour from the oven.

It keep health for the workers and reach environment requirement

Three color caution light (red, yellow, green) and break sense system, which displays working, servicing and. Production condition ,reaches high safety capability.

Adopt SCR simulative 4-20mA high-exactitude constant temp control system, control the brightness of temp and infrared accurately.·

Warm-keeping oven make the glue molecule better activating and reach best attaching efficiency.

Adjustable shoe holder can be adjusted for various kind of shoes.

|

MODEL |

Dimensions(LWH) |

Packing size(LWH) |

Weight |

Production |

Power |

Voltage |

|

DF-155 |

12000*1300*1300 |

|

1100kg |

2000pairs/8H |

38KW |

380V |