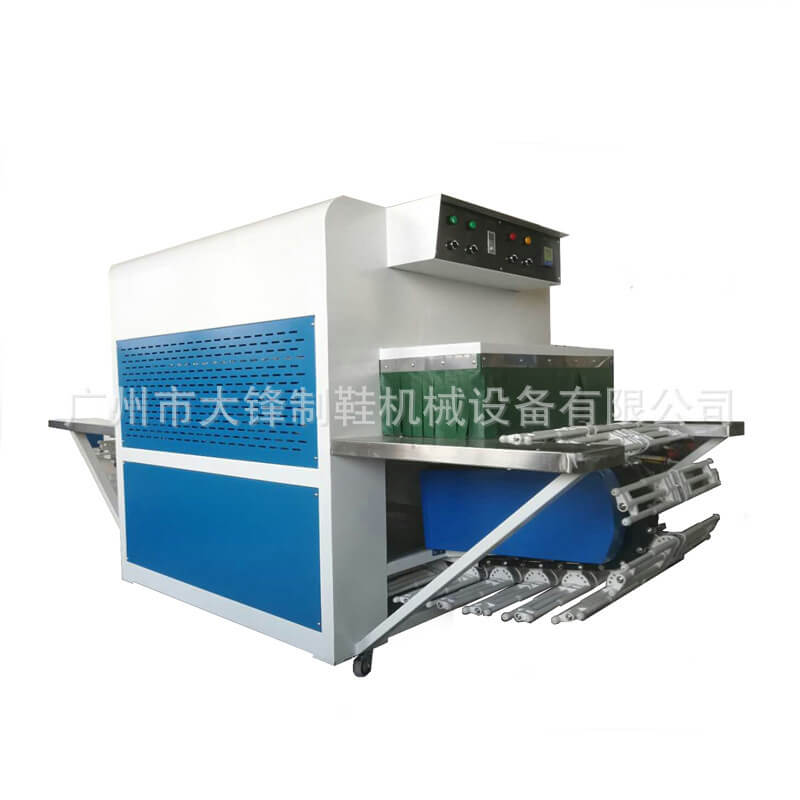

Shoe Hot Air Infra Red Cementing Drying Activating Heating Oven Making Machine

Shoe Hot Air Infra-Red Cementing Drying Activating Heating Oven Making Machine

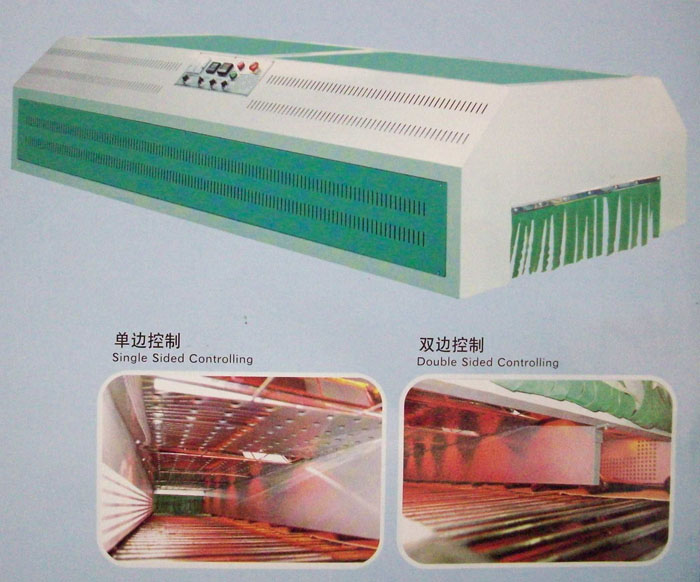

SHOE HOT AIR INFRA-RED CEMENT DRYING & ACTIVATING HEATING OVEN

characteristic: 1. The oven uses fast heating, strong penetration and low radiation infrared tube as heat source, which can be suitable for any type of glue. The design of circulating jet air duct can save more than 30% of energy, and unilateral control can save more than 50% of electricity. 2. Accurate temperature control and good constant temperature effect. 3. Internal circulation duct design, hot air circulation, stable and uniform, uniform air volume Practical effect Leading to the revolution of drying method and realizing high production capacity Replacing hot air drying with light energy drying The ultra short drying line length (1 ~ 1.5m) greatly improves the production efficiency Fast drying and low cost production It can complete the drying of oil / water binder and various solvents in 60 ~ 90 seconds With less equipment investment and space / energy minimization, the production cost can be greatly reduced Improve working environment to achieve high quality The centrifugal fan can reduce the noise, reduce the exhaust of waste heat / exhaust gas, improve the working environment and ensure the health of personnel For different materials of different products, with the best drying method to create the best quality Through real-time automatic temperature control and its data management, the statistical quality management is realized Realize the rationality of production line layout and the simplicity of production operation According to the production conditions of different products, realize diversified production line layout It can control the temperature in real time without preheating before operation

The factory mass production customized various specifications of shoe factory oven

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|