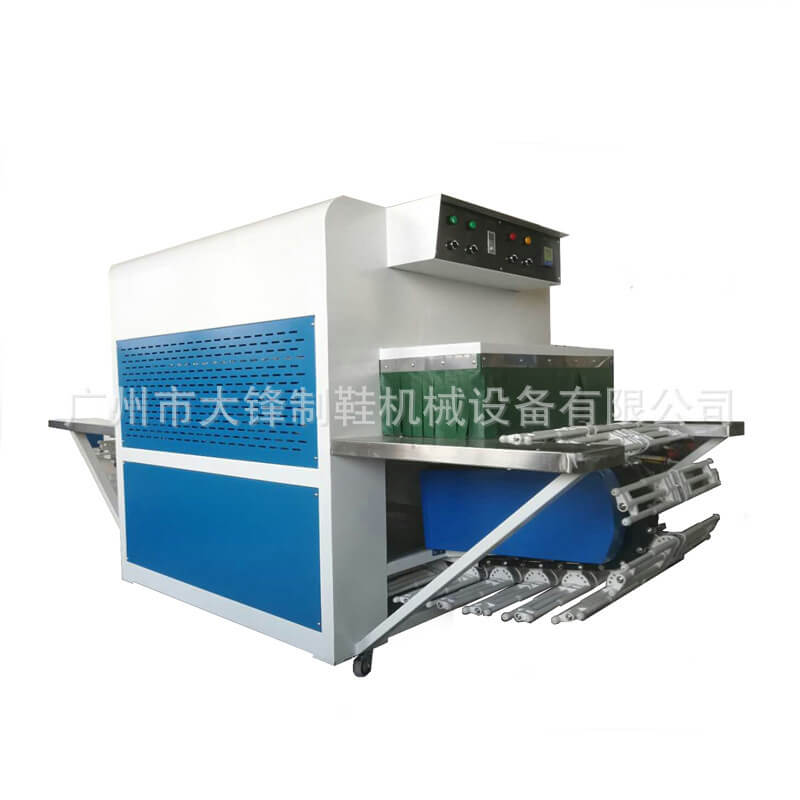

Computer Rotary Chiller Shoes Making Machine High Efficiency Chilling Setting Machine

computer Vertical rotary shoe chiller setting machine shoemaking high efficiency chiller cold setting machine

Characteristic:

1.This machine adopts screw tester with O waste. The rotating distance of the cold-closed area can reach 5 meters.

The cooling temperature is uniform to ensure that the best cooling effect can be maintained and the quality can be effectively improved after entering the cold-dispatch area. The number is more than two times that of the chiller, which is about 30%less than that of the chiller.

2.Innovative double helix multilayer disk track design, smaller size, shorter fuselage.

3.Man-machine interface intellectualization can automatically collect and save data, and can switch the operation status of the interface detection equipment according to customer needs. The operation is simple and conducive to information management.

4.The chain uses precision casting 304 stainless steel and304 stainless steel stents, to ensure that the machine runs smoothlv and more durable.

5.The use of aviation grade low-temperature plastic tray,more durable than other manufacturers, the failure rate is lower.

6.Patent anti jump chain, anti card chain design. Ensure chain runs smoothly.

7.Adopt a 6 original Danfoss compressor.

8.The whole machine is guaranteed for one year, and the chain is guaranteed for two years.

|

MODEL |

Dimensions(LWH) |

Packing size(LWH) |

Weight |

Production |

Power |

Voltage |

|

DF-236D |

1980×1390×1800 |

2080×1490×1920 |

800KG |

1200Pairs/8H |

5KW |

380V |