-

-

- Shoe Production Line Series

- Toe Lasting And Heel Lasting Machines

- Shoe Moulding Machines

- Sole Press Machines

- Shoe Upper Steaming And Softening Machines

- Shoe Steam Heat Setting And Chill Setting Machines

- Shoe Heel Nailing Machines

- Shoe Flattening And Hammering Machines

- Shoe Roughing And Polishing Machines

- Insole And Outsole Making Machines

- Shoe Upper Making Machines Series

- Shoe Sewing Machines

- Leather Measuring And Inspection Machines

- Shoe Cementing Machines

- Others Shoemaking Machines

- Leather Production Machinery

- Shoe Machine Accessories And Tools

-

Shoe Production Line Series

Shoe Production Line SeriesShoe Production Line SeriesShoe Production Line SeriesShoe Production Line SeriesShoe Production Line SeriesShoe Production Line Series

-

Toe Lasting And Heel Lasting Machines

Toe Lasting And Heel Lasting MachinesToe Lasting And Heel Lasting MachinesToe Lasting And Heel Lasting MachinesToe Lasting And Heel Lasting MachinesToe Lasting And Heel Lasting Machines

-

Shoe Moulding Machines

Shoe Moulding MachinesShoe Moulding MachinesShoe Moulding MachinesShoe Moulding MachinesShoe Moulding MachinesShoe Moulding Machines

-

Sole Press Machines

Sole Press MachinesSole Press MachinesSole Press MachinesSole Press MachinesSole Press MachinesSole Press MachinesSole Press MachinesSole Press Machines

-

Shoe Upper Steaming And Softening Machines

Shoe Upper Steaming And Softening MachinesShoe Upper Steaming And Softening MachinesShoe Upper Steaming And Softening MachinesShoe Upper Steaming And Softening MachinesShoe Upper Steaming And Softening Machines

-

Shoe Steam Heat Setting And Chill Setting Machines

Shoe Steam Heat Setting And Chill Setting MachinesShoe Steam Heat Setting And Chill Setting MachinesShoe Steam Heat Setting And Chill Setting MachinesShoe Steam Heat Setting And Chill Setting Machines

-

Shoe Heel Nailing Machines

Shoe Heel Nailing Machines Shoe Heel Nailing Machines Shoe Heel Nailing Machines Shoe Heel Nailing Machines Shoe Heel Nailing Machines Shoe Heel Nailing Machines

-

Shoe Flattening And Hammering Machines

Shoe Flattening And Hammering MachinesShoe Flattening And Hammering MachinesShoe Flattening And Hammering MachinesShoe Flattening And Hammering Machines

-

Shoe Roughing And Polishing Machines

Shoe Roughing And Polishing MachinesShoe Roughing And Polishing MachinesShoe Roughing And Polishing MachinesShoe Roughing And Polishing Machines

-

Insole And Outsole Making Machines

Insole And Outsole Making MachinesInsole And Outsole Making MachinesInsole And Outsole Making MachinesInsole And Outsole Making Machines

-

Shoe Upper Making Machines Series

Shoe Upper Making Machines SeriesShoe Upper Making Machines SeriesShoe Upper Making Machines SeriesShoe Upper Making Machines SeriesShoe Upper Making Machines Series

-

Shoe Sewing Machine

Shoe Sewing Machine Automatic Back tacking, Automatic Pressure Foot Lifting, Automatic Thread Trimmer

-

Leather Measuring And Inspection Machines

Leather Measuring And Inspection MachinesLeather Measuring And Inspection MachinesLeather Measuring And Inspection MachinesLeather Measuring And Inspection Machines

-

Shoe Cementing Machines

Shoe Cementing MachinesShoe Cementing MachinesShoe Cementing MachinesShoe Cementing MachinesShoe Cementing MachinesShoe Cementing Machines

-

Others Shoemaking Machines

Others Shoemaking MachinesOthers Shoemaking MachinesOthers Shoemaking MachinesOthers Shoemaking MachinesOthers Shoemaking MachinesOthers Shoemaking Machines

-

Leather Production Machinery

Leather Production MachineryLeather Production MachineryLeather Production MachineryLeather Production MachineryLeather Production MachineryLeather Production Machinery

-

Shoe Machine Accessories And Tools

Shoe Machine Accessories And ToolsShoe Machine Accessories And ToolsShoe Machine Accessories And ToolsShoe Machine Accessories And ToolsShoe Machine Accessories And Tools

-

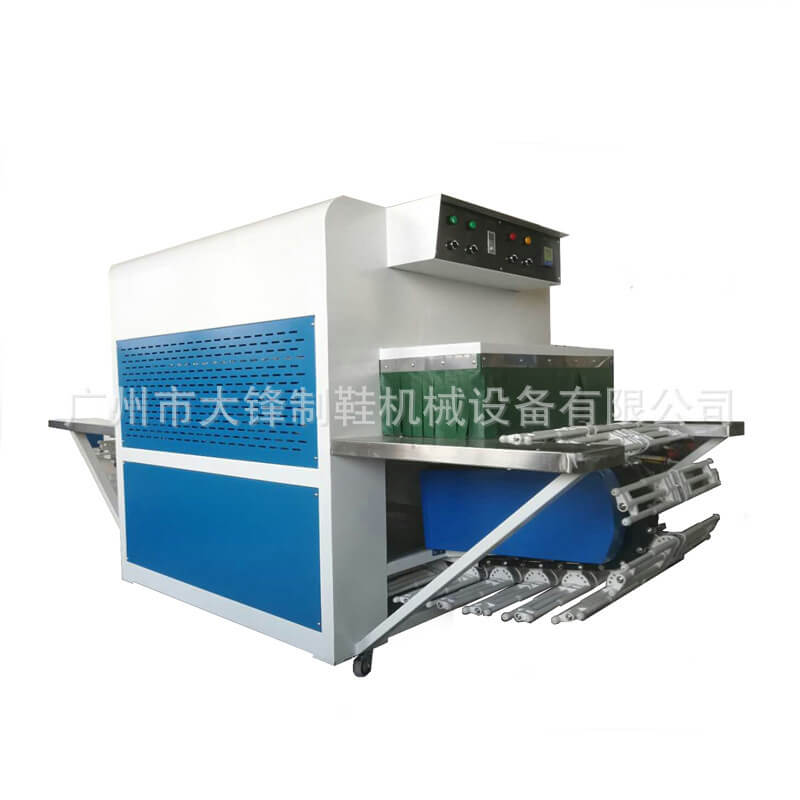

Shoe Vacuum Steam Heat Setting Machine Leather Shoe Making Machine

Push-type Vacuum Forming Heat Setting Shoe Machine Manufacturer

Features:

This machine adopts cart auto in /out design,convenient to operate.

Adopts vaccum setting for matching of vamp and last,improving aesthetic feeling of shoes.

Saves shoe last and reduces manufacturing cost.

This machine adopts close-type vulcanizing system,saving heat and reducing shoes cost.

Save time,increase efficiency and saves enegy.

Increase productivit and stabilize shoe product quality,increase orders.

Large size,low noise,double circulation in wrinkle removing.

Adopts comprehensive steam spraying device,to first soften vamp and then quickly vulcanize and heat and dry and then vacuumize for setting,for better last fitting.

Strengh advantages:

adopts the most advanced german microwave nanodouble circulation vulcanizing system.

Adopts the most advanced german SCP engergy-saving system,which is more stable and more energy-saving than traditional contactor system

Steam softening setting system

More obvious double circuleation in wrinkle removing system.

Fast-speed vacuum setting system

More stable cooling setting system

Easier cart in/out system with automatic lifting

The lowest power consumption is 4.5-6KWH per hour,70% lower than traditional vacuum vulcanizing machine,thermal setting machine.

|

MODEL |

Dimensions(LWH) |

Packing size(LWH) |

Weight |

Production |

Power |

Voltage |

|

DF-868 |

1010*1270*1700 |

1030*1290*1820 |

680KG |

1000Pairs/8H |

10.5kw |

380V |

You may also like

Contact Us

China Dafeng Shoe making machine manufacturer production every shoe machine. Strive to be one of the world's best Shoe production line and shoe making machine suppliers.

If you have any inquiry or question about our products and services, please feel free to contact us. We look forward to responding to your inquiry within 24 hours.

Buy footwear machines from DAFENG and modernize your plant to manufacture high-quality shoes.

Become the next intelligent, lean and efficient factory

Why Choose DAFENG ?

Since its establishment ,Guangdong Dafeng shoemaking machine, adhering to the principle of"integrity,quality,service and communication"

√ Professional production , R & D team

√ Professional factory planning and production process layout design

√ It has been sold to more than 30 countries and regions in the world

√ Fully sealed plywood packaging

√ The whole set of solutions,quality and service are very good

AUTOMATIC SHOE MAKING MACHINE AND SOLUTIONS

Keeping up with new shoe-making technology, we provide highly automated shoe-making production solutions to meet the growing market demand.

EFFICIENT

QUALITY

PROFESSION

SERVE

Tel:+8675781028436 +8613711586658

Whatsapp:+8613711586658

Email:dafengmac@gmail.com tangol@126.com

ADD:18# banxiangang main road industrial area , beisha village , lishui town,

nanhai, foshan, guangdong China.

- Shoe Production Line Series

- Toe Lasting And Heel Lasting Machines

- Shoe Moulding Machines

- Sole Press Machines

- Shoe Upper Steaming And Softening Machines

- Shoe Steam Heat Setting And Chill Setting Machines

- Shoe Heel Nailing Machines

- Shoe Flattening And Hammering Machines

- Shoe Roughing And Polishing Machines

- Insole And Outsole Making Machines

- Shoe Upper Making Machines Series

- Shoe Sewing Machines

- Leather Measuring And Inspection Machines

- Shoe Cementing Machines

- Others Shoemaking Machines

- Leather Production Machinery

- Shoe Machine Accessories And Tools

Products

版权所有 Copyright(C)2018-2022 佛山市大锋机械设备有限公司 粤ICP备14003645号-1