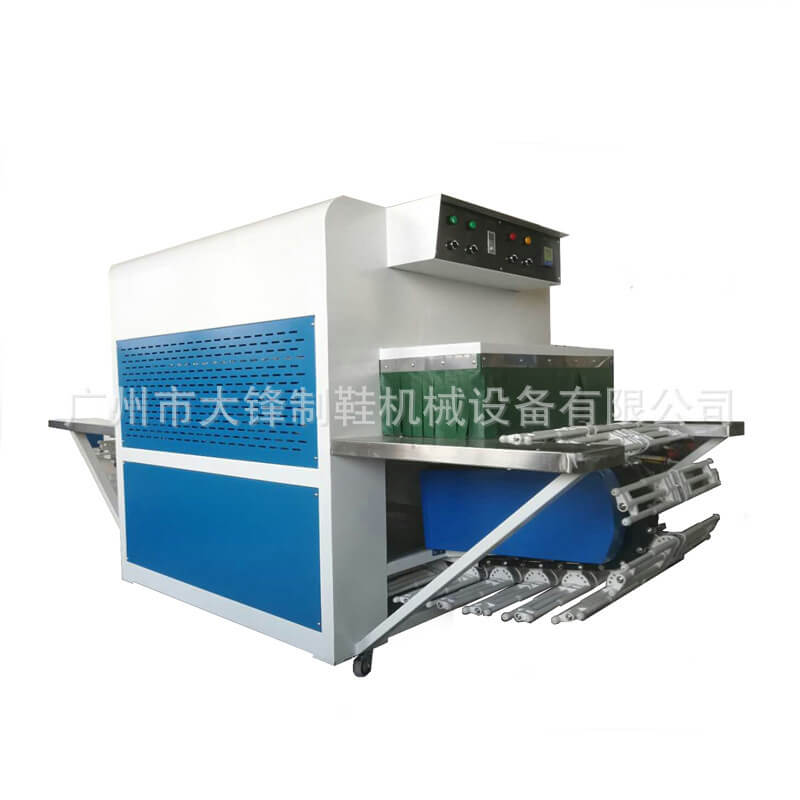

Shoe Making Machine, Shoe Counter Back Part Moulding Molding Machine

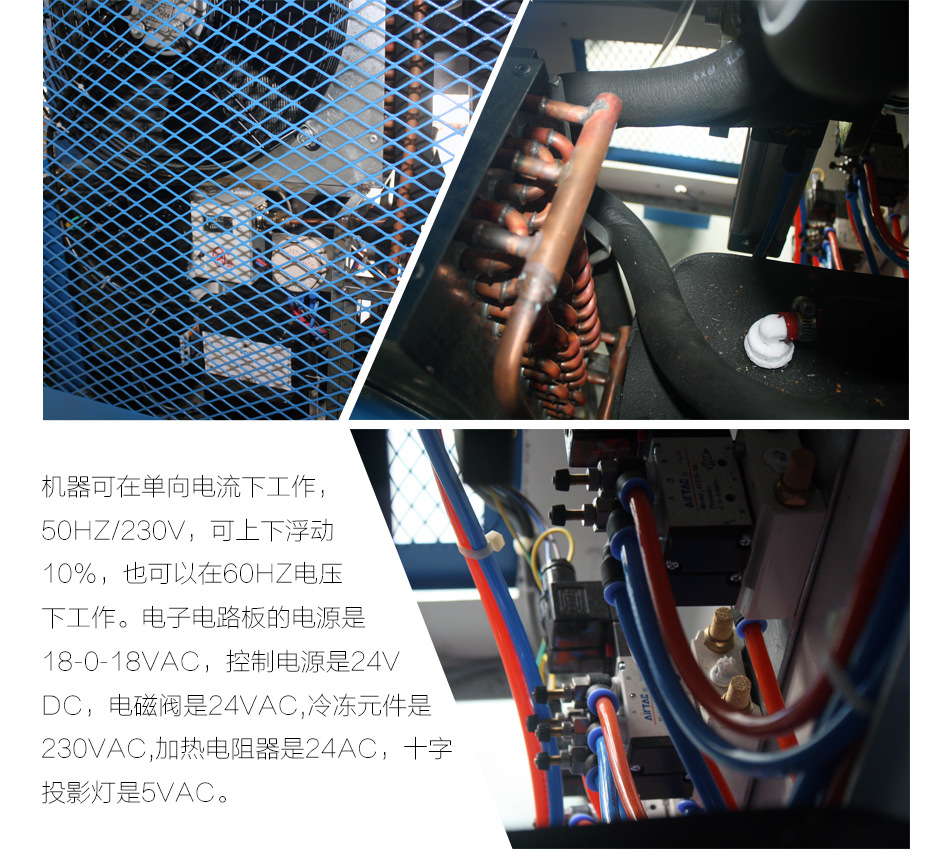

two cold and two hot shoe backpart counter moulding machine

It is with two cooling system and two heating system, has adjustable pull-down grip jaw.

The molds loading and unloading quick and easy.

The mold can be customized to obtain a more perfect shape effect.

Special wiper with eversion, eversion arc large, perfect shape.

The mold can be tilted, more convenient operation.

The adjustable clamp will achieve 100% jointing of vamp with last.

Use of environmentally friendly refrigeration system, cooling speed, freezing temperatures up to-30 °C.

Electronically controlled heating system, temperature control is more precise, the maximum heating temperature of up to 200 °C.

After moulding, the liner, the toe puffs and vamp are closely jointed, without crinkling, deformation and without bubbling.

Micro-electronic processing system.

Rubber sheet downward pressing action mode.

|

MODEL |

Dimensions(LWH) |

Packing size(LWH) |

Weight |

Production |

Power |

Voltage |

|

DF-863 |

890X1450X2000mm |

990X1550X2120mm |

620kg |

1300Pairs/8H |

2.7kw |

220v |