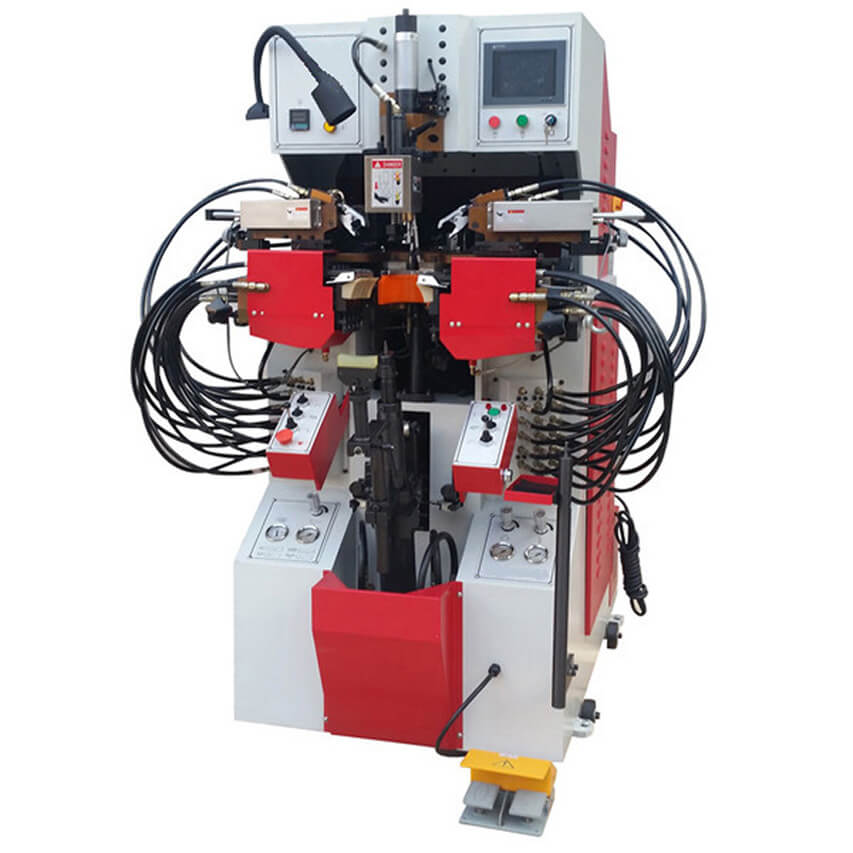

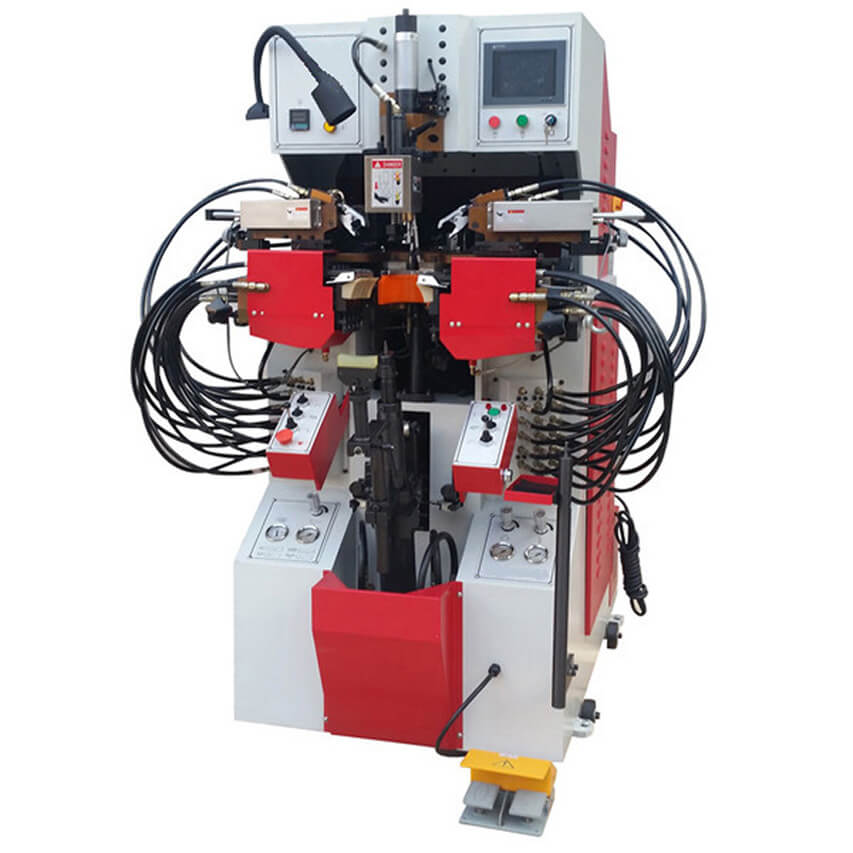

Hydraulic Fully Automatic Computerized Shoe Side And Heel Seat Lasting Machine

Hydraulic Automatic Computerized Shoe Side And Heel Seat Lasting Machine

Features of computer-controlled hydraulic automatic middle and rear helper:

Independent claws inching and pulling up: the left and right claws can be individually set to manually and automatically pull up, and the tightness of the upper can be distributed naturally.

The middle and rear gangs overlap: the middle gang and the rear gang are connected smoothly, and the movements are done in one go.

Last-type claw pull-in function: the claw tightens the vamp and then pulls it inward, so that the inner waist vamp is closer to the last.

Encoder control of the middle help: the track control of the middle shoe rubber and the finger sweeping are more accurate and accurate.

Electric claw position adjustment: touch the switch, the claw can be electrically moved to the best clamping position, providing suitable pulling force.

Touch screen man-machine interface: The humanized control device integrated in the screen is convenient for operation and maintenance.

The elastic tensioner moves up and down: the distance between the automatic balance and the sweeping knife is automatically balanced, and the effect of the rear help is stable and solid.

Computerized action circuit control: PLC action changes are flexible and diverse, control is precise, and troubleshooting is easy.

Front and rear adjustment of the electric tensioner: The position of the tensioner is adjusted electrically, which highlights the implementation of the user-oriented design concept.

Operation parameter memory archive: Up to 30 sets of timers and action parameters can be memorized, which is convenient for changing shoe types.

Separate middle finger mechanism: With the unique oil circuit design, the inner waist is tightly attached to the last, and the effect is perfect.

Intelligent automatic error detection function: timely warning of possible fault points, convenient and fast maintenance.

The operation method of the computer-controlled hydraulic automatic middle and rear helper:

Clean the anti-rust oil; fill in the hydraulic oil: open the cover of the fuel tank, and fill in the hydraulic circulating oil (No. R-68# of China National Petroleum Corporation) about 60 liters inside the lower left cover of the machine; connect the power supply and check the voltage, Professionals should be responsible for this work; check the rotation of the motor: when the motor is started, the pressure of the pressure gauge should rise to 40kg/cm2. If the pressure does not rise, it may be that the running direction of the motor is reversed, just replace any two (phase) of the power cord; before the machine starts to operate, lubricating oil should be injected into each lubricating nipple; after use, it should be turned off Power supply; empty machine operation is strictly prohibited to avoid damage to the machine; keep the machine clean, wipe the outside of the machine body every day after get off work, be careful not to wipe with corrosive volumes such as gasoline and toluene, so as not to damage the machine; pay attention to the electrical box Clean, and it is strictly forbidden to place sundries and conductors; regularly check the pressure rod chute and moving parts, add and replace lubricating oil in time to ensure lubrication; replace the 68# circulating hydraulic oil once a year to ensure that the oil temperature does not rise and prolong the life of the machine; If the machine leaks or seeps oil, you should notify the machine to repair it; ensure that the screws and door covers are complete, fasten all parts of the machine, and strictly implement the operating procedures to check and troubleshoot in time.

Computer-controlled hydraulic automatic middle and rear helper parameters:

Model DF-728DA

Mechanical size (length, width and height) 1650*1350*2200mm

Packaging size (length, width and height) 1800*1450*2000mm

Weight 1070KG

Yield 2000Pairs/8hrs

Power 2HP

| Model | Mechanical Dimensions | Weight | Capacity | Power | Voltage |

|

DF-728DA |

1650*1350*2200 |

1080KG |

2000pairs/8H |

2HP |

380V |