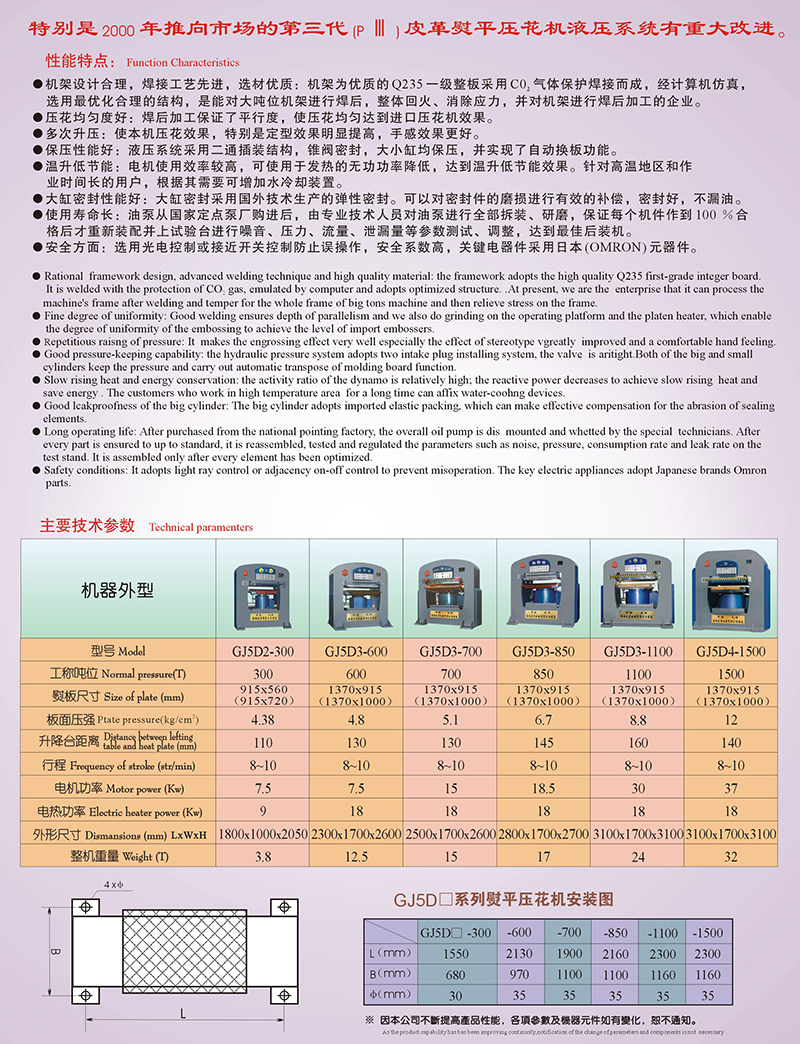

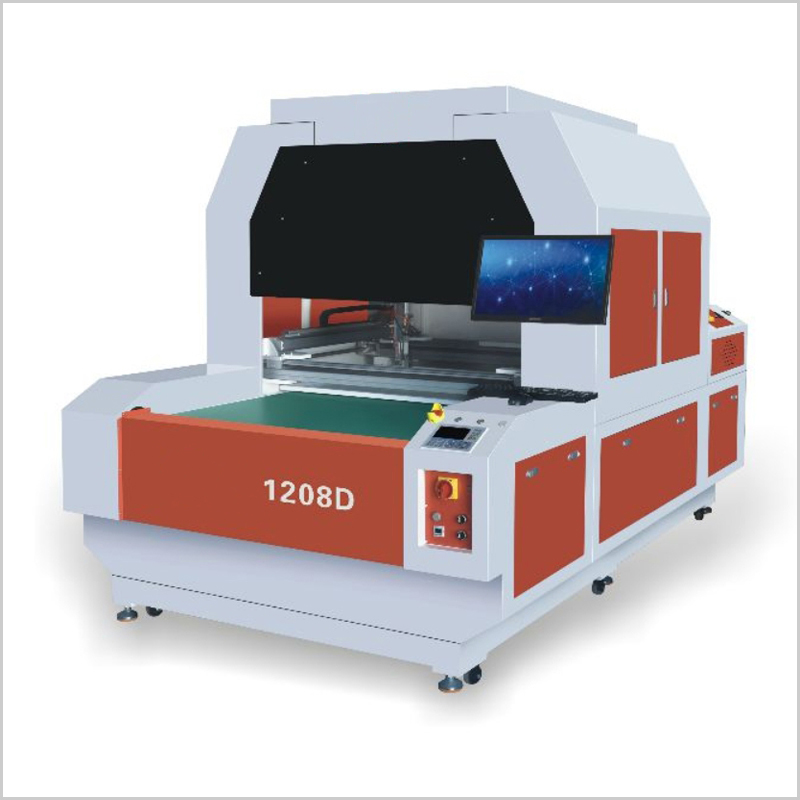

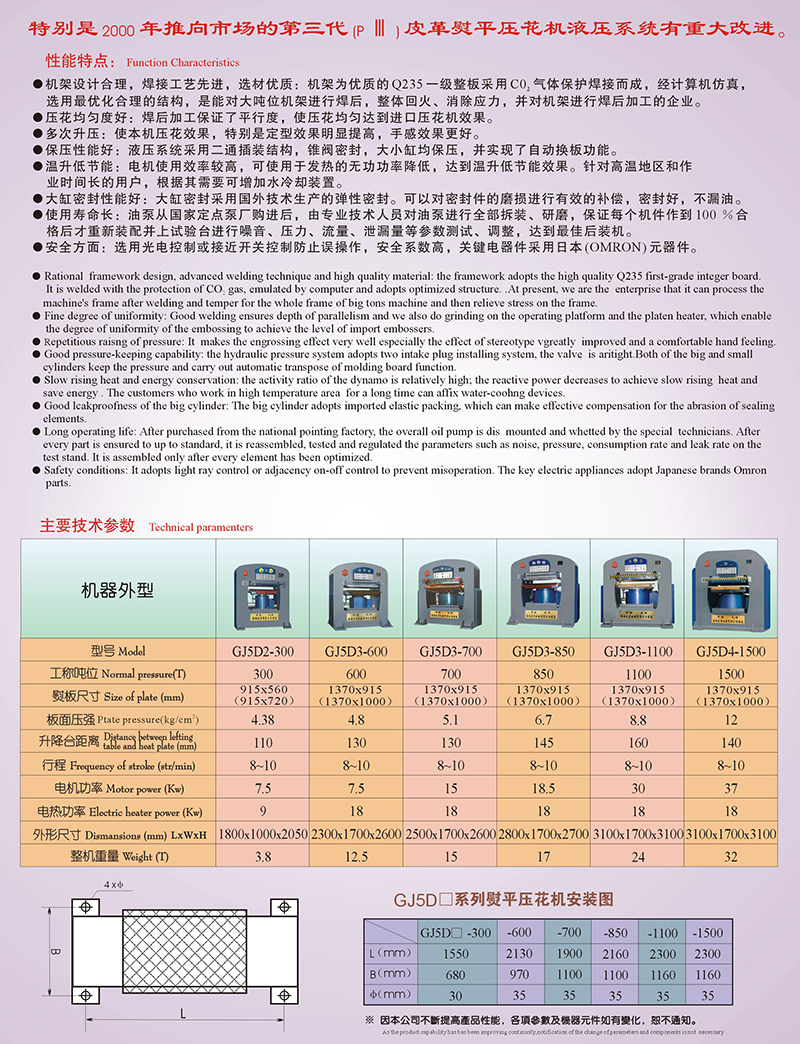

Leather Tannery Industrial 850 1100 1500 Ton Hydraulic Heat Press Shoe Pu Leather Plate Embossing Machine

Leather Tannery Industrial 850 1100 1500 Ton Hydraulic Heat Press Shoe Pu Leather Plate Embossing Machine

GJ5D3-850 Plate ironing &embossing machine

Leather Tannery Industrial 850 1100 1500 Ton Hydraulic Heat Press Shoe Pu Leather Plate Embossing Machine

Rational framework design, advanced welding technique and high quality material : the framework adopts the high quality Q235 first-grade integer board. it is welded with the protection of CO2 gas, emulated by computer and adopts optimized structure. At present, we are the enterprise that it can process the machine's frame after welding and temper for the whole frame of big tons machine and then relieve stress on the frame.

Fine degree of uniformity: Good welding ensures depth of parallelism and we also do grinding on the operating platform and the platen heater, which enable the degree of uniformity of the embossing to achieve the level of import embossers.

Repetitious raising of pressure: it makes the engrossing effect very well especially the effect of stereotype greatly improved and comfortable hand feeling.

Good pressure-keeping capability: the hydraulic pressure system adopts two intake plug installing system, the valve is airtight. Both of the big and small cylinders keep the pressure and carry out automatic transpose of molding board function.

Slow rising heat and energy conservation: the activity ratio of the dynamo is relatively high; the reactive power decreases to achieve slow rising heat and save energy . The customers who work in high temperature area for a long time can affix water-cooing devices.

Good lack proofness of the big cylinder The big cylinder adopts imported elastic packing which can make effective compensation for the abrasion o sealing elements.

Long operating life: After purchased from the national pointing factory the overall oil pump is dis mounted and whetted by the special technicians. After every part is ensured to up to standard ,it is reassembled, tested and regulated the parameters such as noise, pressure, consumption rate and leak rate on the test stand. It is assembled only after every element has been optimized.

Safety conditions It adopts light ray control or adjacency on-off control to prevent mis operation. The key electric appliances adopt. Japanese brands Omron parts.

|

number |

Name |

Place of production |

Model |

|

1 |

plunger pump |

Jiangsu Hengyuan |

HY80Y-RP |

|

2 |

hair felt |

Italy |

1370*1000 |

|

3 |

temperature controller |

TOKY |

6431 |

|

4 |

piezometer |

hongqi |

40mpa |

|

5 |

solenoid valve |

huade |

4WE6D61B/CW220V |

|

6 |

relief valve |

huade |

Dbds6k10b/315 |

|

7 |

valve |

Jining Jinyi |

JYVT400FCV |

|

8 |

electrical machinery |

Weihai Electric |

YB5200-4-30KW |

|

9 |

Electric heating tube |

|

1370*1000 |

|

10 |

Intermediate relay |

IDEC |

RY4S4PDT5AAC220V |

|

11 |

Time relay |

IDEC |

ST3PA-B/22V |

|

12 |

HBTS |

Compton

|

55013-750*9.5 |

|

13 |

electrical equipment |

contactor |

3TF4722/220V |

|

14 |

contactor |

3TB4422/220V |

|

|

15 |

Intermediate relay |

3TH8244/220V |

|

|

16 |

Thermal relay |

3VA6255-80A |

|

|

17 |

Circuit breaker |

3P/100A |

|

|

18 |

wind cooling |

Furunze |

FF30B |

Improvement of embossing machine

Multiple improvements have been made to the valve block and filling valve, resulting in less noise, less heat, and faster speed during the operation of the entire machine.

1. The pressure relief noise is adjustable, and the maximum operating noise of the entire machine is less than 80dB.

2. The hydraulic system is automatically adjusted internally, and there is no phenomenon of plate detachment during secondary pressurization, cylinder chasing or upsetting during cylinder lowering.

3. The filling valve is equipped with a fully closed feedback valve, which makes the starting pressure of the large cylinder more accurate and faster.

4. Improve the material and heat treatment hardness of the filling valve core and valve block plug-in valve, resulting in better pressure retention and longer service life.

5. Using a new type of hydraulic pump, with low leakage, low noise, and long service life.